Removing barriers to vehicle electrification

Mehoo electronics

The future is an electrified world. In fact, the electrification of products, systems and processes is accelerating in countless industrial and consumer environments. Advanced electronics have replaced traditional methods such as hydraulics and pneumatics, driving these transformations.

The acceleration of electrification is most evident in the transportation industry. The number of vehicles equipped with cutting-edge features and pure electric powertrains is growing at an unprecedented rate.

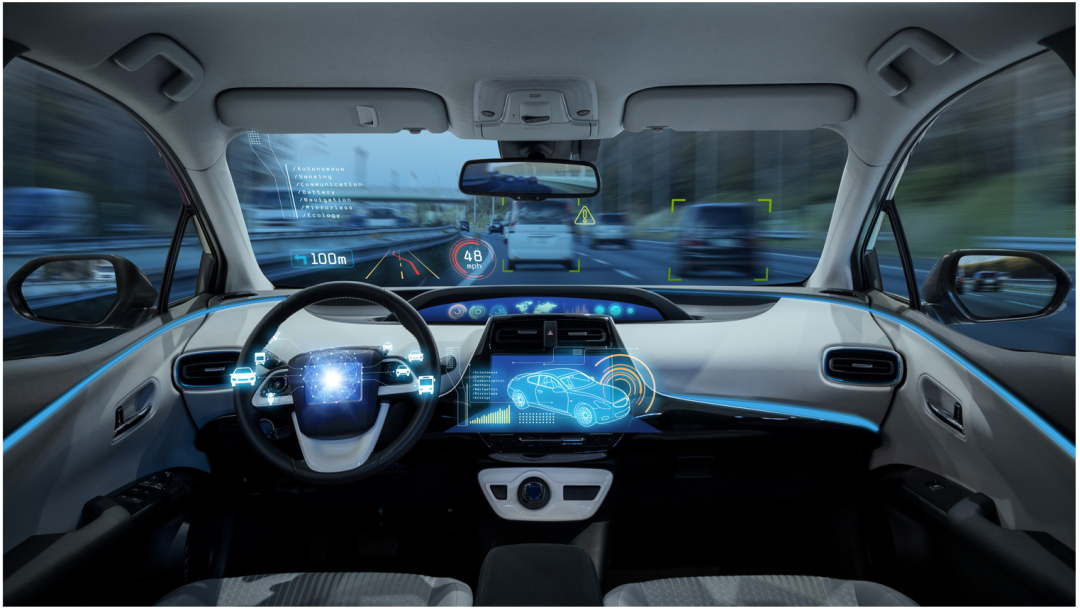

In addition to the rapid replacement of the long-standing internal combustion engine (ICE) by pure electric powertrains, the electric portion of ordinary vehicles is also growing significantly. For example, many critical systems that were previously mechanical have turned to electronics to improve safety and reliability, including brake assist and steering (electric power steering (EPAS)). Recently, solutions to support advanced driver assistance systems (ADAS) are rapidly developing, leading us towards the great goal of "fully autonomous driving".

More choice and better performance will accelerate the adoption of electric vehicles

The number of electric vehicles (EVs) and hybrid electric vehicles (HEVs) has grown significantly globally over the past few years, and they are expected to account for 20% of new vehicle sales in 2025.

In the global market, the number and category of various EV and HEV models, from compact cars to large pickup trucks, has grown significantly. In addition, advances in batteries, power management, and regenerative systems have allowed electric vehicles to continue to extend the range on a single charge, closer to the distance a gasoline-fueled vehicle can travel after refueling. As the range of EVs continues to increase, the concerns that have hindered EV adoption in the past have diminished. And, as the network of charging stations expands and fast charging becomes more common, the "gap" between EVs and ICE vehicles will narrow further, allowing EVs to reach their huge potential.

Challenges of vehicle electrification

Despite the bright future, there are still many obstacles to implementing the electrification of vehicles. What challenges will automakers face to gain a foothold in a $236.3 billion market with a compound annual growth rate of 10.6%?

Despite the bright future, there are still many obstacles to implementing the electrification of vehicles. What challenges will automakers face to gain a foothold in a $236.3 billion market with a compound annual growth rate of 10.6%?

According to the recent "Electrification Innovation in Automotive" survey by Molex and third-party research firm Dimensional Research, industry concerns about barriers to development are real, with 92% of respondents saying their design team There are many challenges in advancing vehicle electrification growth.

Using Zonal regional architecture technology

Consumers demand more from their vehicles than just transportation, so automakers' top priority is to make cars safer, more comfortable, more convenient and equipped with infotainment features. Today's modern vehicles have several excellent features that make the car feel like an extension of the work and living space. However, due to the large number of electronic systems and modules, this brings great challenges to the electrical architecture of ordinary vehicles.

To meet consumer demand, high-end car designs may require more than 100 electronic control units (ECUs). The proliferation of ECUs in vehicles has created significant challenges in how to connect, package and manage traffic-driven command and control-specific functions that are critical to the vehicle. As existing architectures reach the limits of scalability, the industry needs to adopt Zonal architectures. People can divide the vehicle into different zones to assign functions, and then pass information between zones as needed. Zonal zone architecture not only optimizes and reduces the overall wiring volume, but also integrates ECUs. In addition to enabling a topology better suited to the growing number of electronic systems in a vehicle, Zonal regional architecture can also reduce vehicle weight, thereby increasing efficiency and improving range per charge. Successful implementation of a regional architecture requires the use of high-speed data connectivity technologies that are robust, robust, and capable of keeping data flowing securely.

According to the survey results cited above, 84% of respondents agree that the adoption of Zonal regional architecture is the future and will help alleviate concerns that traditional approaches are reaching their limits. Molex can provide a variety of solutions to facilitate the transition from existing traditional methods, smooth through all intermediate stages, and ultimately generate a variety of industry-leading flexible application products to support the realization of a true Zonal regional architecture.

Thermal Risk Management

With the rapid growth of electronic components designed to be incorporated into vehicles, including internal combustion engine vehicles and electric vehicles, thermal management challenges also arise. What happens when an electronic device such as a computer or mobile device overheats? They switch off, which is absolutely unacceptable for vehicles traveling at high speeds on the road. So what does a customer need to design for a vehicle that now has more than 100 ECUs and multiplying electronics? These issues increase the complexity of the design, requiring the industry to innovate in connector miniaturization due to space constraints. This has a large impact on the temperature levels of automotive systems, which must be addressed through clever innovative design solutions and advanced predictive modeling.

Miniaturization and the addition of motorized components will inevitably increase component density. Due to the reduced surface area of a miniaturized system, dissipating the same or more heat in a smaller space can create an overheating risk that must be managed and controlled. The risk of overheating may increase if the electronics are in a sealed ECU and are located in areas of the vehicle where extreme ambient temperatures occur (such as under the hood). Harsh environments combined with the high circuit density and small package size requirements of next-generation connectivity systems can present thermal challenges if not properly designed. To address thermal issues in connectors, companies must seriously address safety, reliability, and longevity issues during the project design phase. Molex implements high-fidelity thermal simulation methods to drive design exploration and mitigate thermal issues prior to mass production. The traditional "build then test" approach to next-generation connected systems is less efficient due to the cost and lead time of building a test model. Thermal simulation provides instant visibility, allowing customers to speed up modification cycles. Molex can provide customers with tailor-made solutions to meet their needs in terms of performance and long-term production.

It brings new challenges to the new technology of noise reduction for electric vehicles. Traditionally, the operation of internal combustion engines has suppressed ambient noise from the road, tires, wind and vehicle structure. Without an engine to mask these noises, vehicle occupants may experience discomfort, reduced dialogue quality and drone-fatigue. Engineers can no longer rely on mechanical noise reduction methods (such as the use of sound-insulating materials or foam-lined tires), which add cost and weight to the vehicle, negatively impacting the car's energy consumption and range, both of which are electric vehicles the two keys.

Molex's world-class noise cancellation sensor (RNC sensor) allows automakers to electronically reduce unwanted sounds. Our accelerometer-based road noise cancellation sensors are mounted on the vehicle chassis to monitor road noise and, by incorporating intelligent algorithms, emit noise cancellation waves the moment the noise enters the occupant's ears. Noise management technology brings broader noise reduction benefits to OEMs, allowing automakers to lead the way in designing and deploying lighter, higher performing, more flexible and more efficient solutions to reduce noise.

A bright road to electrification

The continued growth in the proportion of electric vehicles and the electrification of vehicle powertrains are inevitable developments that are positive and beneficial to the automotive industry. It is important that seasoned innovators such as Molex and Molex need to collaborate extensively with the automotive ecosystem to support this megatrend. We are a leading supplier of electronics and connectivity solutions to most of the world's largest OEMs and suppliers in the automotive industry, striving to stay at the forefront of design needs, reduce potential risks, and develop solutions for thriving vehicles The market meets the demand. We ensure that our company's products, tools and processes provide reliable solutions for the automotive industry, and by providing effective guidance, our customers can use our design solutions with confidence and help them forge a golden path to a bright future of electrification.